Home > Painting > Powder coating

DECOZINC POWDER COATING

DECOZINC powder coating is an “anti-corrosion” and decorative duplex treatment of the GALVA UNION group. It consists in applying a layer of powder paint on galvanized or metallized steels after mechanical or chemical preparation of the part. This single-layer system is ideal for atmospheres up to the C4 corrosivity category.

It provides a lifetime of work frequently than 25 years and provides a resistant, durable and environmentally friendly coating.

OUR ACHIEVEMENTS IN PUCTURE

STEPS IN THE DECOZINC PROCESS

The most important phase of the process is the preparation of the part before powder coating. It consists of several phases to ensure a quality powder coating.

- Deoxidize and make clean

The preparation goes first by cleaning the piece. This includes a chemical pickling (homogeneous, controllable and non-aggressive process for the galvanized coating), followed by cascading rinsing with tap water and demineralised water to remove the mineral salts that cause separation.

- Degas and protect

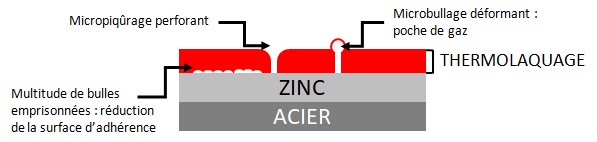

After cleaning, the part will be degassed at a temperature of 230 ° C. The degassing step is mandatory to allow a better adhesion of the paint on the part by eliminating hydrogen and gas present under the surface of zinc. Degassing also limits the appearance of micropilling or microbulling, which can cause adhesion and appearance defects in the part coating (see diagram below).

The final step in the preparation is to apply a film-forming product to create a surface conversion to improve the protection of the zinc under the paint and the adhesion of the powder-coated coating. This chrome-free product is environmentally friendly.

- The powder coating

The final step in the DECOZINC range is to automatically or manually apply an architectural grade polyester powder coating by electrostatic effect. The piece is then polymerized in an oven at 160/200 ° C.

OUR ACHIEVEMENTS IN DECOZINC

The Tamarins Route benefited from duplex treatment with maximum protection against corrosion in aggressive environments. A number of elements have also been treated by the DECOZINC range.

The catenary poles of the T4 tramway in Lyon have also benefited from DECOZINC galvanizing and powder coating treatment.

Galvanizing and powder coating treatment DECOZINC was also used for NIGLOLAND, the amusement park located in the Aube.

CHOOSE A PLANT